I even picked up spare ink and a washout sales space whereas I was there. Gauntlet RS 8/10 Automatic PressI paid just $10,000 for this high-end computerized press. A vendor supplied me the identical mannequin about 2 years earlier for greater than $25,000! I even financed the press by way of the shop that was closing, spacing out payments over a yr. The shop additionally gave me a rotary screw compressor, holding tank, and 48” Sprint dryer for a music.

It is obtainable in a quantity of different sizes, and the worth proven is for the 10″ x 14″ choice. Ryonet, Blackmax, Rite Film, and so forth. are some well-known brands providing a selection of display screen printing films and different inject film transparency replacements. After getting that info, will in all probability be straightforward for you to decide the usability of a machine.

You can print the inkjet film that you are going to need to make the screens. So to sum up, all you need is a computer, an inkjet printer, and vector software program like CorelDraw or Adobe Illustrator.

If you’d rather purchase the items of your screenprinting kit individually, this selection from Speedball is simply the frame, so you ought to buy the options and squeegee individually. The frame is made from sturdy hardwood, and the mesh is produced from a 110 monofilament material that makes for extra precise outcomes.

There are even greater bargains to be had with automatic presses. While it is actually plenty of work to interrupt down and transport an automated press, you're saving hundreds of dollars versus purchasing it new. This is used to strip the emulsion off the display screen after we wish to re-use it. Moreover, you additionally need some ink whether or not it's plastisol or water-based, an ink solvent used to wash up plastisol ink out of your display screen and free the squeegee.

The devoted T-shirt palate confirms the correct positioning and good printing impact. The most important feature of this display screen printing machine is that you can rotate both the palate part and display frame half freely at 360 levels.

It is efficient at removing ink stains, clogs, grease, or other blockages from mesh openings on and off the press. However, it can be a little aggressive on emulsions, hence guarantee to test before you apply it to your stencil. The line-up for our inkjet switch papers includes SingleJetâ„¢ II for mild colour clothes, SingleJetâ„¢ Opaque for DARK attire, Jet Pro Active Wear and others.

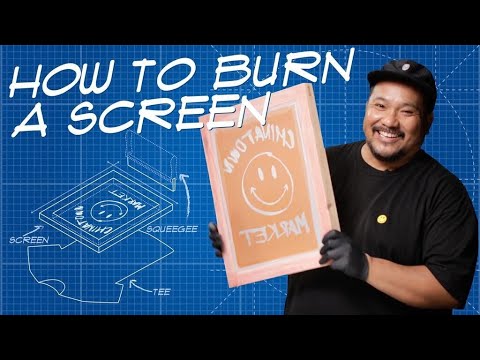

You need to apply this part, as it could be tricky for model spanking new customers, and you may get all of the ink onto the picture space. Now, as you see the blue traces, you must hold the display screen up to the light, and you have to wash the excess off just utilizing water.

So, you'll find a way to belief their merchandise with out having any doubts in your thoughts. When establishing a home enterprise, dimension is a significant factor—depending in your workspace.

You can also contact Regional Supply for skilled evaluations and custom display screen printing system installations. For novices, dual-core emulsion is beneficial extremely for ease of utility. During mixing the emulsion, attempt to handle and mix it in an setting away from gentle to keep the emulsion usable. Emulsions can be used as much as three months whether it is combined, saved, and handled correctly. This is the variety of holes in a given area of mesh screens.

You don't need employees hunched over or sitting down, as a result of they’ll inadvertently waste lots of time sitting down and getting up. People also are most likely to get a little bit lazy when they sit down. A single 8 foot pallet rack prices greater than $350 from ULINE when you purchase it new. I purchased sixty four linear feet for $600 simply by going to a shifting sale for a local warehouse. I had to break it down and relocate it – admittedly time-consuming – nevertheless it was easily worth the $2,000 or so that I saved. M&R KruzerBought it from a used equipment supplier for $2,200 while it retails for $3,500. Sold it for $1,four hundred in a while once we began shifting to automated.

Screen printing is achieved through a process that includes applying thick inks atop of a garment quite than soaking the ink into the garment. One colour at a time is utilized that means that an extra display screen is required for each separate shade in the design. Join our Facebook group and easily purchase, sell, or commerce your personal display screen printing equipment. If you hear a couple of display printing shop near you that's going out of enterprise – run, do not stroll. Visit their location for better offers, quite than relying on the internet. The greater the shop, the higher offers you can find – screen printing ink they will have extra stuff to eliminate. With these screen printing necessities equipment, you get the simplest time and no problem, which I consider are going that can assist you screen print better.

The products have good market value, and sellers can supply merchandise at a low price. Besides, many people love to use display screen printers to shock their associates or household with unique t-shirts. For stability, as an alternative of a bracket, the screen printing press offers a set of screws for fixing the plate onto the pallet. Another very important thing to note that the floor of the platen is barely pitting. That helps you for handy scraping of the pallet glue in the installation process. Assembling the screen printing machine is simple and simple. The unit comes with a helpful consumer manual, and you additionally can discover some useful videos online.

This unit can be more than able to working as a backup solution to bigger corporations with an extensive manufacturing amount. For those who are simply starting the printing business, this machine can be your best place to begin. Because of the increasing demands of work and private aspirations, screen printing is rising in popularity. Screen printers use pressed ink through a stencil mesh and produce a design on a number of fabrics.

That all comes at a very reasonably priced value, and you're going to get what you're paying for. Today, there are numerous display screen printing presses on the current market. Among them, some are dominating the market with their high quality and repair. Before committing your self to a selected display screen printing machine, be sure to have asked your self what exactly you propose on using your machine for. As there are many designs out there for many functions, asking your self this query will enhance your possibilities of investing in the right machine to satisfy your whole needs. Try your finest to find out how a lot merchandise you might be producing and what quantity of colors you want to work with—keep an open thoughts and take into consideration future initiatives.

Size will also determine the merchandise you propose to work with and should be thought of if you plan on shifting your machine with you from location to location. Keep in thoughts that larger objects, such as bed sheets and banners will require a bigger machine, just don’t neglect that these bigger machines are not as portable. Choose a smaller possibility when you have restricted area to start out out with and plan on working with smaller gadgets corresponding to t-shirts and clothes. Suitable for working with a big number of materials, this machine is ideal for any small enterprise or individual printing store. With its two-station, 4 shade design, this machine permits for a staff of two to provide up to t-shirts an hour. Complete with an independently rotating display screen layer and pallet, this machine is ideal for multi-color printing.